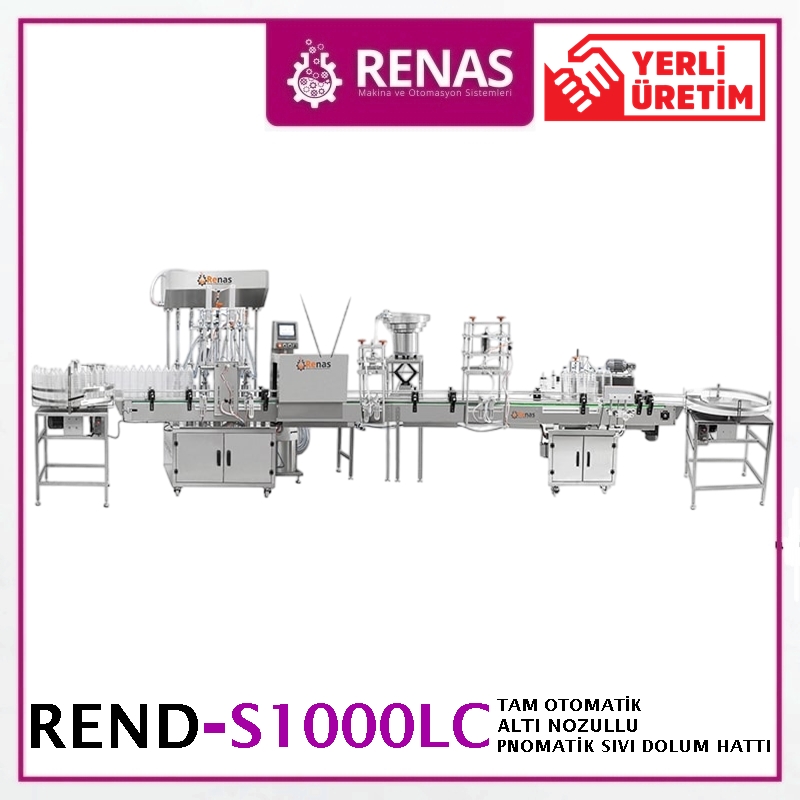

Full Automatic Liquid Filling Line of 100-1000ml

General Features of 100-1000ml Liquid Filling Line

The fully automatic liquid filling line is a very suitable filling line for entrepreneurs who are looking for a liquid filling line for industrial projects..

It consists of 5 machines in total. The filling range of the filling line is between 100 ml - 1000 ml. With the fully automatic liquid filling line, you can reach an average production level of 1,000 pieces per hour. You can produce an average of 35 products per minute.

The fully automatic liquid filling line can be used for filling dozens of different liquid products with different densities. For example, we can give examples of products such as buttermilk and molasses. Thanks to the clamps that fix the bottles, the product does not cause situations such as missing during filling.

Since it has 4 nozzles, it offers a faster and more efficient working environment. As a matter of fact, it can work in accordance with many types of lids. It provides full control thanks to its functional and easy-to-use menu.

You can work in harmony with many types of labels in labeling processes performed on the fully automatic 2-nozzle liquid filling line. The machine points that touch the product offer a hygienic working environment as they are made of stainless material and cleaning processes are extremely simple.

100% domestic production. Therefore, spare parts and service of the liquid filling line are easily accessible.

Since it is a liquid filling line operating with high precision, there is no deviation in product weight.

Filling line; The following machines may vary according to packaging, cap type or product characteristics.

- Supply Tray:To send the packages in sequence to the filling machine's convoyer system

- Filling Machine:To fill the product into the packages in the desired weight

- Lid Seaming and Sealing Machine:To automatically align and close the lids of packages

- Labeling:For labeling packages with self-adhesive labels

- Collection Tray:To collect the packages from the labeling machine at the end of the line Each machine in the line works in synchronization with the previous machine for optimum working capacity.

If you request additional (optional) features for the machine you have chosen, the delivery time of the machines is between 5-20 days. Product cargo is packaged in accordance with long-distance shipments. Renas Makina has a contracted cargo company. In this way, you can provide product transportation at a more affordable price. If your own company has a contracted cargo company, you can also choose to use that cargo. 1 year warranty is provided against fabrication defects.

.png)